Signum

RPU® spray technology for polyurethane boots and clogs manufacturing.

Automatic rotary machine

12 – 14 – 16 stations

Available in the following configuration:

RPU®; RPU®|RPU®; RPU®|PU pouring:

Polyurethane boots with RPU spray technology

The “RPU Spray Technology” and revolutionary mould-holder system has let Stemma to develop an innovative process, now available in the new “SIGNUM 20” machine for polyurethane boots.

The process guarantees an increase in productivity of about 30% compared to the traditional process. Moreover, makes it possible to create extremely light products with particularly thin thicknesses, representing an effective innovation that improves the production and characteristics of the boot.

The uniform distribution of colour, the high grip of the sole and the possibility to use a wide range of linings are other characterising aspects of this new machine.

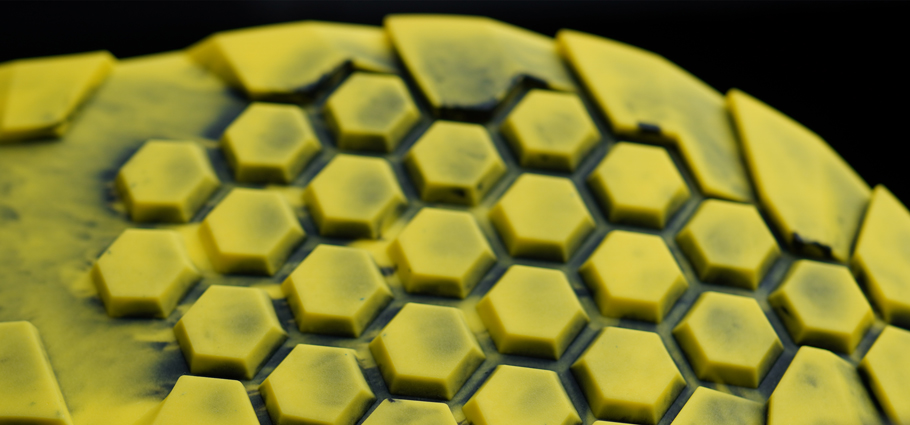

Polyurethane clogs with RPU spray technology

With RPU® Spray Technology also clogs with extremely defined surfaces can be made. Looking at them, you notice a sort of polyurethane stiffer skin, which contains within itself a softer polyurethane that ensures comfort and cushioning.

A perfect system for health and safety footwear, where polyurethane can ensure durability (it deforms less easily), anti-static and anti-slip conditions.

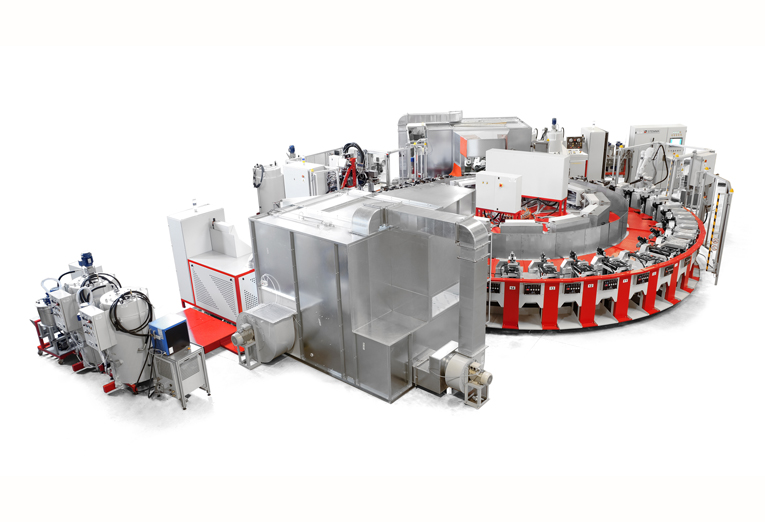

Fmx

RPU® spray technology for soles manufacturing.

Automatic rotary machine:

24 – 36 stations

Available in the following configurations:

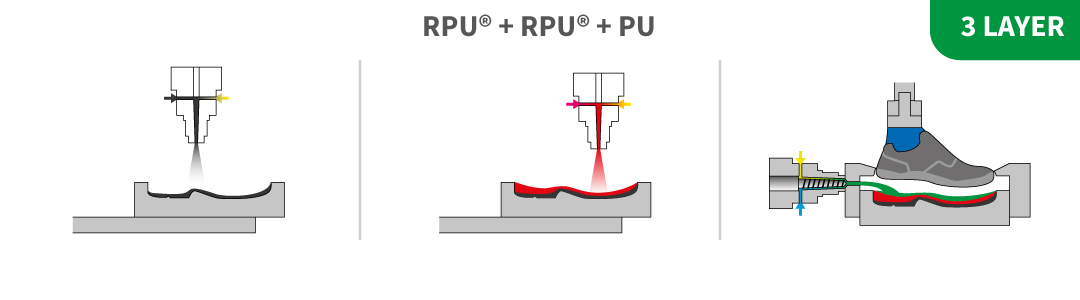

RPU®; RPU®|RPU®; RPU®|PU pouring; RPU®|RPU®|PU pouring;

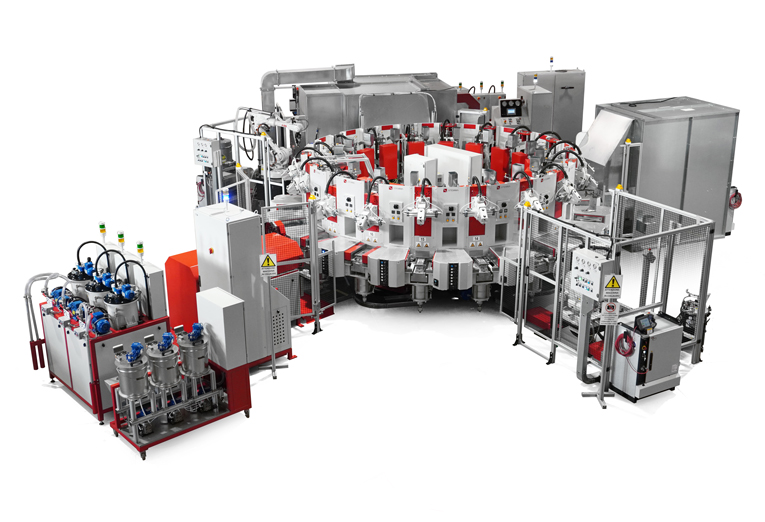

Formula RPU

RPU® spray technology combined with PU direct injection on upper for shoes manufacturing.

Automatic rotary machine:

18 – 24 – 30 – 36 stations

Available in the following configurations:

RPU®; RPU®|PU; RPU®|RPU®; RPU®|RPU®|PU; RPU®|PU|PU;

SIGNUM LAB

Automatic rotary machine for small productions or samples, for R&D footwear departments.

Available in the following configurations:

RPU®; RPU®|PU;

2 – 4 – 8 stazioni