A trend that has found a new confidence with FORMULA latest-generation of machines by STEMMA.

A trend that has found a new confidence with FORMULA latest-generation of machines by STEMMA.

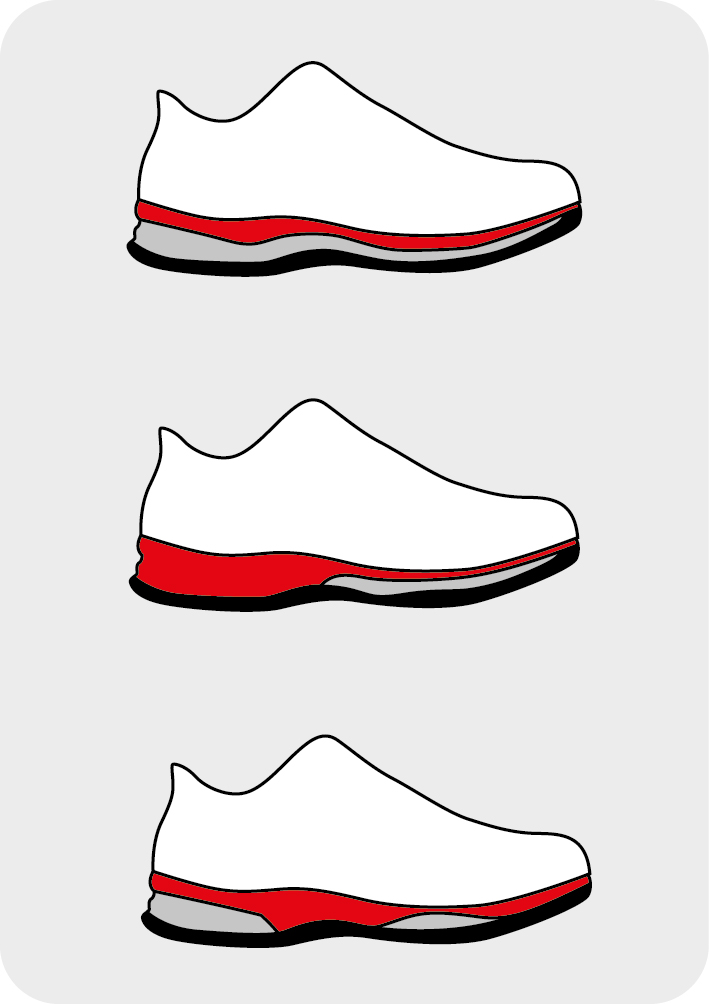

Three density shoes are a revolution for direct injection on upper machines, which for several years had remained unvaried in the types of product that could be produced.

Soles produced by polyurethane double injection combined with a pre-moulded tread in rubber or TPU (PLUS2 technology), or, as per the latest innovation presented, made using a single integrated process (SWAP system) with tread obtained through TPU pouring or by polyurethane injection or spraying.

Technologies that, thanks to their potential, have found their best application in the production of technical footwear (running, outdoor, military) and especially safety shoes. They in fact allow the features of the sole to be optimized, combining the specific properties of the materials used between them (e.g. hardness, rebound, lightness), to create shoes with an innovative design, with new aesthetical and functional solutions in which the polyurethane of the sole is integrated with the upper to create protections or stiffening elements.

The solutions developed by STEMMA stand out for productivity and efficiency, which remain unaltered when compared to traditional dual density productions. The processing units are perfectly integrated in a completely automated system, which allows less manpower to be used, while guaranteeing high technical and qualitative standards for the product.

You can find this article also on Safety magazine – Edizioni AF, (pag. 26/27): https://edizioniaf.com/issues/safety_012021/